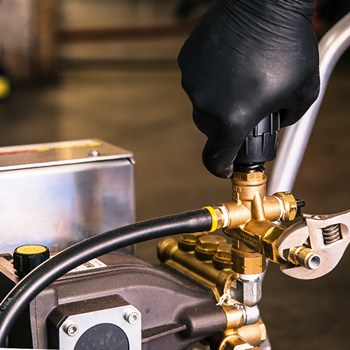

To fix a pressure washer, identify issues that can be related to the malfunction, such as low water pressure, water or oil leaks, the engine, increased noise, the detergent injector, and use the right set of tools and accessories, like screwdrivers, sockets and ratchets, Hex/Allen keys, wrenches, needle-nose pliers, and a utility knife.

How to fix a pressure washer based on the causes is detailed below.

Troubleshooting for Common Pressure Washer Issues

Troubleshooting for the most common pressure washer issues include low pressure, leaking, pressure washer won’t start, the pressure cannot be shut off, pulsating pressure washer, the pressure washer is running rough or it is noisy or the soap is not dispensed from the reservoir is explained below.

1. Low Pressure on a Pressure Washer

If a pressure washer is low on pressure, the accumulated dirt in the pressure washer pump or the nozzle should be cleaned or replaced. A pressure washer might be low on pressure if the water source is not fully open or if the pressure washer hose has kinks and the water is leaking.

If water is not running through the pressure washer hose after it is connected to the pressure washer’s inlet and the pressure washer is low on pressure, remove the inlet filter and clean it.

If pressure washer pressure is dropping seconds after the unit is turned on, the nozzle or the unloader valve should be cleaned.

2. Leaking Pressure Washer

If the seals on pressure washers are worn out, water or oil will leak out of the pressure washer. If the pressure washer pump is leaking, replace the pump seals, tighten the bolts, rebuild the pump assembly, or the pump itself. The pressure washer pump can be leaking if the thermal release valve is defective.

3. Pressure Washer Won’t Start

If an electric pressure washer won’t start, plug it into a different socket or use another extension cord. Cords longer than 25 feet need 12-gauge wires to work properly since lighter gauges can’t provide enough power for the pressure washer to operate.

If an electric pressure washer won’t start, plug it into a different socket or use another extension cord. Cords longer than 25 feet need 12-gauge wires to work properly since lighter gauges can’t provide enough power for the pressure washer to operate.

If a gas pressure washer doesn’t start, it could be low on gas. If the pressure is accumulated in the pressure washer trigger gun, squeeze the trigger gun to release the pressure. Replace a defective spark plug if a pressure washer won’t start or change the position of the choke.

If a pressure washer hasn’t been running for a long time and the engine won’t start, it could be that old fuel has clogged the carburetor. Drain old fuel from the carburetor and start the pressure washer. A pressure washer won’t start if the carburetor passages are clogged. This article explains in detail how to clean a carburetor on a pressure washer.

4. The Pressure Cannot Be Shut Off

If a pressure washer cannot be shut off, stop the engine, and remove and replace the unloader valve if it is defective. If the unloader valve is defective, releasing the trigger wand won’t switch the valve into bypass mode and water will be flowing out of the pressure washer wand and the valve should be replaced.

5. Pulsating Pressure Washer

A dirty discharge valve or inlet makes a pressure washer pulsate. The discharge valve or inlet should be cleaned every 5 to 6 uses. A defective plunger can make a pressure washer pulsate even if the discharge valve and inlet are clean and should be replaced.

If a pressure washer is pulsating and the pump is sucking air, turn off the pressure washer without turning off the water supply and squeeze the trigger gun to release pressure.

If the pressure washer’s pressure is spiking, the unloader valve should be adjusted.

6. Pressure Washer Is Running Rough

A pressure washer connected to a faucet that runs cold and hot water can be running rough. If a pressure washer is connected to a cold water faucet, the cold water can get trapped in the hose to warm up, which can cause the pressure washer to run rough.

If enough air is not entering the inlet, a pressure washer will be running rough. The inlet should be cleaned or replaced if it is obstructing the airflow. A damaged crankcase can cause the pressure washer to run rough if it is not using hot water and should be replaced.

7. Pressure Washer Is Too Noisy

If a pressure washer is noisy, the engine or the pump doesn’t have enough oil and new oil should be added. A pressure washer can be noisy if the water intake is blocked and it should be cleaned or replaced.

If a pressure washer is not winterized and all water is not drained before storage, the frozen water will damage the inner parts of the pressure washer and it will produce noise once started again.

8. Soap Is Not Dispensing From the Reservoir

If the soap is not dispensing from the reservoir, high pressure in the pressure washer pump is preventing the nozzle from drawing the soap. Replace the nozzle and ensure the pressure washer is getting enough water to be able to draw the soap. If the soap is not dispensing from the reservoir, it could be that a soap inlet tube filter is clogged and it should be flushed with clear water.

How to Fix a Gas Pressure Washer?

To fix a gas pressure washer that won’t start or that stops running when it is in use, fill it with gas, check oil levels and refill it with oil if necessary, clean or replace the air filter. If oil is dripping from the gas pressure washer engine, replace the seals. If a gas pressure washer won’t start, a spark plug wire should be reconnected or the entire spark plug should be replaced.

To fix a gas pressure washer that won’t start or that stops running when it is in use, fill it with gas, check oil levels and refill it with oil if necessary, clean or replace the air filter. If oil is dripping from the gas pressure washer engine, replace the seals. If a gas pressure washer won’t start, a spark plug wire should be reconnected or the entire spark plug should be replaced.

Should You Always Open Up a Pressure Washer to Fix It?

A pressure washer shouldn’t be opened up to be fixed if it is still under warranty since it would affect the warranty. If a pressure washer is not under warranty, it can be opened to be fixed.

Tools You Need for Fixing Pressure Washer Issues

Tools needed for fixing pressure washer issues are listed below:

- Sockets and ratchet

- A rubber hammer or mallet

- Snips

- Utility knife

- Screwdrivers

- Needle-nose pliers

- Hex/Allen keys

- Wrenches