In order to fix a pressure washer pump, there are a few things the owner can check, before taking it to a service shop. The water flow level, warranty, pressure washer pump tire, pump oil, and water source can easily be verified. With a little understanding of the pressure washer’s essential parts, a few minor repairs can be performed by the user with no difficulty.

The pump is a significant part of the pressure washer because it adjusts the water flow and supports the entire assembly to work properly. If the pump is damaged, the pressure washer will not perform as intended.

Checklist Before Fixing a Pressure Washer Pump

1. Check the Water Flow Level

The water flow level is a good indication that something is wrong with the pump.

The water flow level is a good indication that something is wrong with the pump.

1.1 Lower or zero water flow

If lower than expected, it can be the result of clogged pipes or the connection to the water source might be damaged. Insufficient or dirty water flowing through the unit can ruin the pump. The first thing to look for is a clean and clear intake valve and filter screens. Then, the other valves and O-rings should be analyzed for any indication of leakage.

Low water flow can usually be caused by three main reasons: not enough inlet water supply, obstructed inlet water filter, and none or wrong nozzle.

If the inlet water supply is insufficient, the garden hose should be unlinked in order to make sure that the water coming from the tap has enough pressure. Also, it is important to use a garden hose that is large enough for the pressure washer used. The user manual should provide this information.

In case the inlet water filter is blocked, the garden hose should be disconnected from the power washer and all the debris removed.

The nozzle might also be an issue, so it is important to make sure that the correct one is being used.

If zero water flow, it is a clear indication of a defective pump. In such an instance, it is recommended to shut the pressure washer off and start the repair process.

The two main causes for this issue are usually a faulty unloader valve or broken pump inlet valves or manifold. For the first case scenario, the unloader screw should be adjusted, and the seals and springs ought to be checked for any damages. For the second scenario, the pump must be disassembled the components of the inlet manifold should be replaced or cleaned, depending on the case.

1.2 Higher water flow

If higher water flow, the pump’s inlet valves or manifold might be damaged. In this case, the pump should be disassembled and the components of the inlet manifold ought to be replaced or cleaned thoroughly.

Another cause for a higher water flow could be the pump sucking air, in which case the power washer should be turned off, without shutting down the water supply. Then, the trigger gun should be squeezed in order for the pressure to be released.

A clogged nozzle, gun-spray wand, or water inlet filter can also lead to high water flow. In such a case, a needle can be used to clear the nozzle, clean water to cleanse the water inlet, as well as vinegar for removing possible deposits in the spray gun or wand.

A damaged pump can also cause high water flow, in which case the pump ought to be replaced.

2. Check the Warranty

Warranty is a very important aspect to check in the case of a faulty power washer’s pump. If the machine is still in its warranty period, then no effort must be put into any type of repair. Most manufacturers offer one or two years warranty for their products, but the periods differ for various parts. Therefore, there are pumps with even four years of warranty.

The first thing that needs to be checked is if the product is still under warranty, and then the conditions imposed by the manufacturer must be met. In such a case, trying to repair the pump by the buyer could lead to the termination of the warranty.

Some sellers do not have a physical location for repairing pumps, but they can offer the assistance needed by providing a repairman.

There are many sellers that have return policies for pumps that are brought back in 30 to 60 days, which means that if the item is discovered to be faulty within this period, it can be replaced with a new one.

3. Check Pressure Washer Pump Type

The type of the pressure washer’s pump is another important aspect that has to be taken under consideration when preparing it for a repair. There are three main types of pressure washer pumps: wobble, triplex, and axial cam pumps. Not all types can be repaired, especially at home.

The wobble pumps are sealed shut from the factory because of their complex construction and parts. Wobble pressure washer pumps are not generally available for repair as they have very small parts in places that are extremely difficult to reach.

Triplex pumps release high pressure and are usually designed for professional use. These pumps can last thousands of hours of use without needing any maintenance. Repairing a triplex pump is easy because the replacement valves are quite accessible.

Axial cam pumps are less powerful than triplex pumps but better than wobble pumps. This type is also very difficult to repair due to pieces that are in hard-to-reach places.

4. Check Pump Oil

Checking the oil is another thing that should be performed when the pressure washer is manifesting strange behavior. The level of the oil inside the power washer’s pump can affect the functionality of the machine.

Checking the oil is another thing that should be performed when the pressure washer is manifesting strange behavior. The level of the oil inside the power washer’s pump can affect the functionality of the machine.

The first step of the process is to read the user’s manual in order to find out which is the right level of the oil.

The second step is to find the viewing glass on the pressure washer’s pump. Its exact location can also be found in the user’s manual. The glass viewer of the pump should either have a small red dot in its center or two parallel lines. The oil in the pump should be up to the red dot or between the two lines, depending on the model.

Oil has a very significant role in the functionality of the pump and the power washer itself. Its purpose is to lubricate internal parts in order to minimize friction, corrosion as well as overheating. If the oil level is too low, the pump will wear very fast and might fail permanently.

In case the oil level is too high, it can damage the pump. It is not recommended to run the pressure washer with overfilled oil. The excess should be wiped-cleaned before using the machine.

5. Check Water Source

Insufficient or dirty water can also be a reason why the pump of a pressure washer is not functioning properly. If the water that goes through the pump is not sufficient or if it is dirty, it can seriously damage it.

Power washers need large quantities of water to operate as intended. Water must come from the source with enough pressure to feed the unit and be able to deal with the power flow generated by the machine that is ultimately sprayed through the nozzle.

The most common water source used by pressure washers is an outside tap. Some power washers have their own water storage unit. Also, there are users who do not have an outside tap and use an indoor one or a bucket. Either way, the quantity needs to be enough for the unit to run smoothly.

It is also extremely important for the water to be clean. If it is dirty, debris can easily clog into the pressure washer and pump and damage it.

Minor Repairs to Fix a Pressure Washer Pump

Besides the methods mentioned above, there are a few more minor repairs the owner can do on the pump of the pressure washer.

1. Siphon the Pump Oil

Siphoning the oil can be done quite easily by first checking the oil level. Through the vision glass, one can see if the oil is cloudy. If the oil seems cloudy, it is a sign that there is a combination of vapor, usually because water got in it. In such an instance, the oil can be siphoned using a siphon that extracts the entire quantity of oil and then refills it with fresh, clean oil.

It is important to note that power washers use a certain type of oil. In order to find out which type is most suitable for a particular unit, it is recommended to read the user’s manual.

In order to change the oil in the pump, there are a few steps that the user should do. First, the pump should be purged by turning on the water supply and removing the wand from the spray gun. Then, the engine should be started. The power washer gun trigger ought to be held for about two minutes in order for the residual water and dirt to be released. Since the unit heats up during this process, the dirt can be removed much easier.

Draining the oil

The next step is draining the oil as well as the fuel from the engine. In order to relieve the pressure inside, the reservoir top access bolt needs to be loosened and unscrewed using a wrench. Removing the oil can be done by draining it from the base of the oil pan with an oil drain plug, by using a suction gun to suction the oil out, or with a manual or electric pump. For this process, it is recommended to use an oil pan or tray so that the oil doesn’t spill all over the place.

It is important to consider the local regulations and store the oil in order to dispose of it accordingly. After draining the entire quality of oil, the knob or bolt can be put back in its place.

The new oil can be poured into the pressure washer but only after consulting the user’s manual. There are types of oils that already come in pre-measured bottles. Usually, non-detergent pressure washer pump oil should be used. With the help of a funnel, 3/4 of the way full of oil should be poured in.

Once the necessary quantity of oil is in the pressure washer, the bolt should be put back in place and tightened. Any spilled oil near the cap and around should be wiped thoroughly. The power washer ought to be put in an upright position, and it can be used after a few minutes.

2. Use the Primer

Priming the pump can also be a solution when the water flow is low. This can be done using the primer that is on the side of the power washer. In case the water flow level is still insufficient when turning on the unit, the discharge hose should be disconnected. After releasing the air from the pump, the discharge hose can be reconnected, and the machine turned on again.

3. Clean the Chemical Strainer

If the chemical strainer is clogged, the entire unit will underperform. It can also generate a strange noise making it seem that the pump is damaged.

Cleaning the chemical strainer involves unscrewing it from the hose. Then, the strainer should be run through clean water while using a brush to remove any possible debris.

After installing the chemical strainer back to the hose, the power washer should be working properly. If not, clearly the problem is a different one.

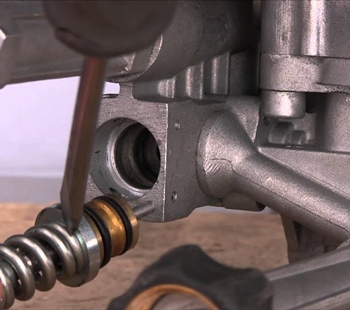

4. Check the Thermal Release Valve

The thermal valve keeps the water within the pump in a consistent thermal range in order to limit the recirculation of the water from the pump so that it does not over-heat.

The thermal valve keeps the water within the pump in a consistent thermal range in order to limit the recirculation of the water from the pump so that it does not over-heat.

If the released water is too hot, it means that the seals within the pump are damaged and can cause a lot of problems.

Most power washers have thermal discharge valves located at the base of the pump’s mechanism. Its role is to release water from the pump when it gets too warm.

In case the valve is damaged, it is recommended to change it immediately or the extensive heat can damage the entire unit.

5. Replace the Pump

When all else has failed, the pump might be damaged beyond repair. When that happens, the pump should be replaced with a new one. This is also a task that can be done at home with a few right tools.

The first step is to find a suitable pump, that is compatible with the model of the pressure washer. Depending on the type, a new pump can cost anywhere between $100 and $400. All the information regarding the specs of the item can be found on the bottom of the pump. It is also important to buy all the necessary parts, not only the pump itself.

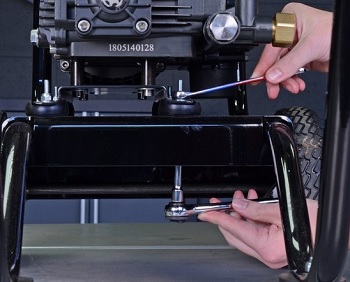

Removing the old pump

In order to remove the old pump, all the nuts have to be unscrewed. It is also important to remember all of their locations which can be done by marking them. Once the screws are open, the pump has to be pulled out of the pressure washer with care. This process should be done slowly and without using force, not to end up breaking other parts.

The new pump should be placed in the same way the old one was. New screws ought to be used and not the old ones. They should be tightened carefully not to damage the pump. Once the pump is replaced, the pressure washer should be functioning without any more issues.